Page 6 - May-June2025 Vol 43 No 1

P. 6

STATEWIDE By Michael Brewster

Underground Innovation

Trenchless Pipe Rehabilitation Solutions Across Tennessee

Necessity truly is the mother of consuming, and expensive. Trenchless for cities, counties, and other municipalities

invention, especially in underground pipe rehabilitation refers to a range of when replacing aging infrastructure that is

utility construction. techniques utilized to restore or replace not structurally deficient.

Trenchless methods have become damaged water, sewer, storm drain of While additional investment is

essential for completing complex other pipelines without digging up, typically required up front, the long-term

infrastructure projects efficiently and removing, and replacing the existing pipe. benefits can be substantial. Instead of

with minimal disruption, according to Trenchless technology such as PVC fold replacing storm drains, sanitary sewer

Walker Building Group, Nashville-based and form, cementitious spray applied liner lines, and other utilities, trenchless

underground utility construction leader. (SAPL), slip lining and cured-in-place pipe rehabilitation instead can deliver

With more than two decades of pipelining (CIPP) offers a more efficient significant benefits, including:

experience completing critical public solution. It is a less disruptive alternative • Decreased traffic interference

and private infrastructure projects, the

company has found that in many cases,

there is no need to excavate and replace

every pipe on every project.

New Solutions Borne Out of Experience

Their stellar reputation as a traditional

“dig and replace” contractor served as a

powerful catalyst in seeking new solutions

to complex underground utility projects

across the state. They knew there had to

be a better answer each time they were

challenged with:

• Addressing subsidence in the roadway

caused by deteriorated pipes buried in

the East Tennessee hills

• Completing preventative maintenance

on pipes located adjacent to sewer and

gas lines beneath neighborhoods mid-

state

• Restoring infrastructure below I-40 in

West Tennessee.

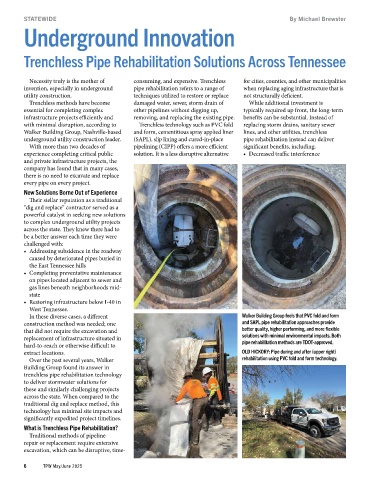

In these diverse cases, a different Walker Building Group feels that PVC fold and form

construction method was needed; one and SAPL pipe rehabilitation approaches provide

that did not require the excavation and better quality, higher performing, and more flexible

replacement of infrastructure situated in solutions with minimal environmental impacts. Both

hard-to-reach or otherwise difficult to pipe rehabilitation methods are TDOT-approved.

extract locations. OLD HICKORY: Pipe during and after (upper right)

Over the past several years, Walker rehabilitation using PVC fold and form technology.

Building Group found its answer in

trenchless pipe rehabilitation technology

to deliver stormwater solutions for

these and similarly challenging projects

across the state. When compared to the

traditional dig and replace method, this

technology has minimal site impacts and

significantly expedited project timelines.

What is Trenchless Pipe Rehabilitation?

Traditional methods of pipeline

repair or replacement require extensive

excavation, which can be disruptive, time-

6 TPW May/June 2025